Changing Landscape for Compact Equipment

The demand for compact equipment has surged as industries seek solutions that combine efficiency, versatility, and space-saving design. Modern workflows increasingly prioritize machines that can navigate tight spaces while maintaining performance and durability. This evolution has driven manufacturers to rethink traditional designs, focusing on mobility, adaptability, and ergonomic functionality to meet dynamic operational needs. Compact equipment is no longer just about size—it’s about intelligent integration of features that enhance productivity and reduce operational strain.

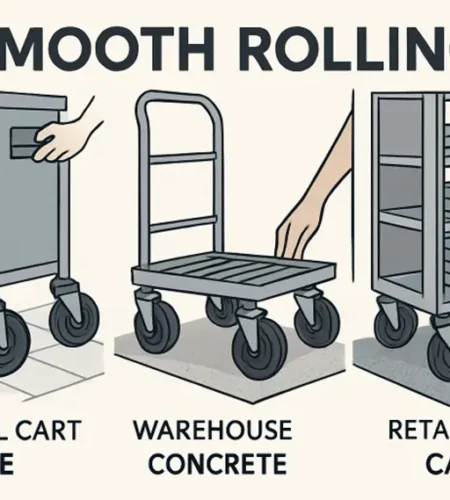

This shift has elevated the importance of components like stem casters—versatile devices designed to enable smooth, reliable movement in complex environments without sacrificing maneuverability or stability. By incorporating these into modern compact equipment, designers can ensure enhanced control, safer operation, and seamless transport across diverse surfaces, supporting the growing demand for flexible and efficient solutions.

Core Components of Mobility Solutions

Modern mobility systems are designed for adaptability and safety, featuring locking systems, impact-resistant construction, and ergonomic mounting solutions. These features ensure compact equipment performs reliably on uneven or congested surfaces. Advances in caster technology improve maneuverability and resistance to tipping, maximizing uptime and minimizing maintenance and repair, making them an attractive investment for high-traffic environments.

Balancing Safety and Reliability

With increased mobility comes an enhanced focus on safety and reliability. A significant share of workplace injuries stems from poorly designed or malfunctioning rolling equipment. Practical solutions are therefore engineered with advanced tread patterns, auto-lock technology, and materials that withstand heavy use while ensuring the well-being of both operators and bystanders.

Mobility systems must be aligned with environmental factors such as load requirements, surface smoothness, and frequency of use to create a safer workplace. Regular maintenance and proper product selection are just as vital—they reduce operator strain, streamline workflows, and ultimately drive down the incidence of workplace accidents.

Future Trends in Mobility Solutions

Innovations in mobility solutions are transforming compact equipment mobility. The industry is adopting recycled materials and eco-friendly manufacturing processes to reduce environmental impact. IoT-enabled casters and mobility components track usage and maintenance schedules, optimize movement patterns, and boost efficiency and cost savings. These intelligent features align with sustainability and digital transformation objectives. As technology advances, experts anticipate further tracking, automation, and energy conservation improvements for small equipment applications.

Sustainability in Equipment Mobility

Manufacturers increasingly use eco-friendly materials in mobility components, such as recycled nylon and low-VOC finishes, to reduce carbon footprints and maintain high durability. This sustainable manufacturing approach doesn’t compromise strength, as modern caster options offer resilience and end-of-life recyclability. Proper maintenance extends equipment life cycles and reduces costs, benefiting financial performance, corporate sustainability goals, and brand reputation.

Choosing the Right Mobility Solution

Choosing the proper mobility solution requires a thorough understanding of the equipment’s needs and operational environment, including load capacity, frequency of use, floor surfaces, environmental exposure, and safety features. Consulting with industry professionals and user feedback is crucial for a successful selection process. Field testing multiple options before large-scale deployment ensures the chosen solution meets longevity, maneuverability, and safety standards, leading to smoother operations and reduced maintenance costs.

Conclusion

In fast-paced industries where every minute counts, the proper mobility solution for compact equipment can transform productivity, safety, and sustainability. Integrating advanced features, prioritizing eco-friendly materials, and embracing intelligent technologies ensures organizations thrive within modern workspace constraints. By focusing on wise mobility choices, businesses lay the groundwork for efficient, safe, and future-ready operations.

Comments